An Euroregion Project validates metal additive manufacturing of satellite antennas

The project Validdantenness has been successfully concluded by corroborating the short-term advantages that metal additive manufacturing can bring to the telecommunications sector, especially when applied to antennas for small satellites or smallsats.

Validdantenness (validation de la fabrication additive d’antennes pour applications spatiales) was considered with the aim of observing the benefits and disadvantages of new metal additive manufacturing techniques compared to conventional manufacturing technologies commonly used in this type of applications.

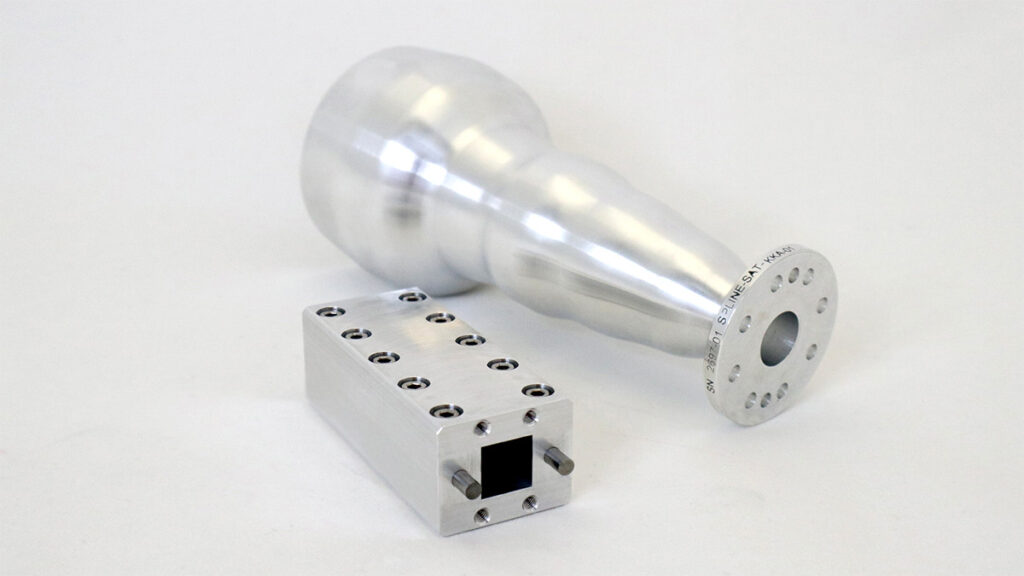

To this end, two communication radiating chains for small satellites were designed, simulated, manufactured and analyzed. One of the specimens was manufactured with CNC machining techniques and the other by means of additive metal manufacturing (SLM – Selective Laser Melting or powder bed fusion).

After subjecting both components to electromagnetic response measurements and environmental tests (vibration and thermal cycling), the Project has shown that the radiant chain made with SLM offers similar performance to that of the chain made with CNC, with a weight reduction of around 50%.

Furthermore, the metallographic analysis confirms the potentiality of the SLM technology, since the percentage of set defects in the tested samples is very low and no major defects have been found.

Bearing in mind that a larger number of antennas will be required in a satellite, it is very important that their size and weight be optimal without sacrificing performance, in order to save costs. This importance has increased since the appearance of the New Space, which has democratized access to Space for small companies with smaller budgets.

The small satellite industry is one of the fastest growing segments in recent years within the space sector. Therefore the importance of a project like Validdantenness which boosts the Euroregional Aerospace Value-Chain and which is source of future business opportunities.

Validdantenness, which has been developed between February 2021 and July 2022, has had the financial support of the Nouvelle-Aquitaine / Euskadi / Navarra (New Aquitaine / Basque Country / Navarre) Euroregion.

Companies and Innovation Agents from the three Territories with complementary and multidisciplinary profiles participated in its consortium: Anteral (project leader), Microlan Aerospace, LISI Aerospace Additive Manufacturing, Centro de Tecnologías Aeronáuticas (CTA), NAITEC and the Basque Aerospace Cluster (HEGAN).